Description

REEF-SPEC Carbon

Red Sea REEF-SPEC™ Carbon is the ultimate choice for marine & reef aquariums due to its unique technical characteristics.

REEF-SPEC Carbon is available in 100g /3.5 oz, 250g /9 oz, 500g /18 oz, and 1000g /35 oz containers.

Red Sea REEF-SPEC Carbon’s granule size and its micro/macro porous structure, ensures a very high total adsorption capacity and rapid extraction of the specific organic pollutants that are found in Reef aquariums.

REEF-SPEC Carbon has extremely low phosphate leaching and minimal ash content while also not affecting the pH of aquarium water.

Red Sea REEF-SPEC Carbon needs replacing less frequently than carbons that are not reef-specific or are of a lower quality and represents an effective, cost-efficient solution for providing the very best water quality in marine & reef aquariums.

Main features

- Rapid removal of organic pollutants

- High total adsorption capacity

- Ultra-Low phosphate output

- Ultra-Low ash content

- Suitable for Marine & Freshwater

- Filter Bag included (100g, 250g, 500g, 1000g)

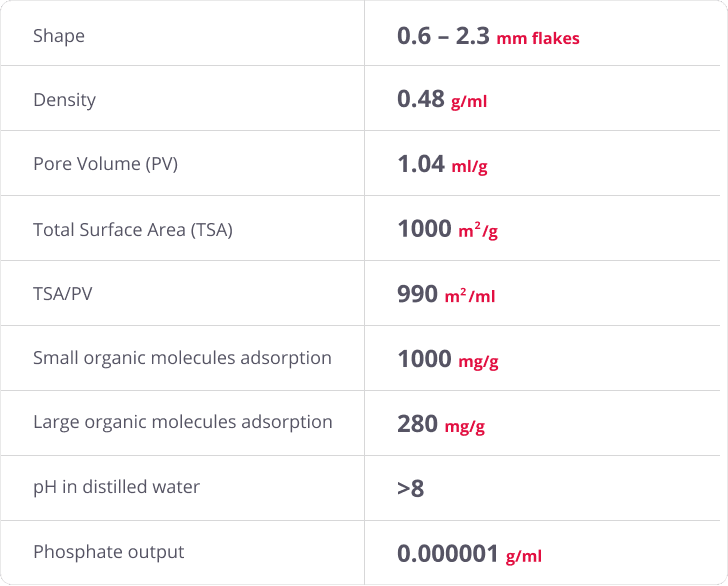

REEF-SPEC Carbon specifications

The role of activated Carbon in the reef aquarium

Why do we need to use Carbon in a reef aquarium?

There are organic pollutants that can only be removed from reef aquarium water by active Carbon.

The reef aquarium is a closed artificial ecosystem where living creatures continually produce organic waste consisting of proteins, fats, carbohydrates, organic acids and phenols.

If allowed to decompose the organics will fuel the activity of many unwanted microorganisms in the aquarium, increasing the total oxygen demand (BOD, COD) which will cause a reduction in Redox potential, as well as causing excessive production of CO2 by bacterial respiration, which will reduce pH.

Furthermore, there will be an increase in nitrogenous and phosphorus compounds, encouraging growth of nuisance bacteria and eventually of nuisance algae. The accumulating organics also has a significant effect on light penetration, especially in the blue and near UV spectrum that stimulates coral growth.

Stripping out the organics from the water is therefore crucial for the success of the aquarium. Using strong protein skimming, fine mechanical filtration and healthy biological filtration (nitrification and de-nitrification) will treat the large organic particles and the end products of the organic decomposition processes. However, there are many small organic particles that can only be treated by very fine mechanical micro-filtration using activated Carbon.

How does activated Carbon filter water?

Scientifically speaking, Carbon removes the organics from water by a physical process called adsorption. Within a reef aquarium, the submicroscopic pores of activated Carbon is the final stage of the mechanical filtration process, adsorbing the organic molecules that are too small to be removed by even the finest mechanical filters or physically removed from the water by protein skimming.

Adsorption can be thought of as the adhesion of a molecule to surface by attractive forces. This occurs within the submicroscopic pores of the Carbon because the attractive forces between the organic molecules and the internal surfaces of the Carbon are far greater than the attractive forces that keep them dissolved in solution. This will continue until all of the surface area inside the Carbon is used up and it becomes saturated with organics.

What is activated Carbon?

Activated Carbon is an extremely porous material with a sponge like structure but with a very large internal surface area relative to its physical size. It is produced from many organic materials that have a high Carbon content such as coconuts shells, nutshells, lignite, bituminous coal or anthracite. The Carbon-based material is “activated” through physical modification and thermal decomposition in a furnace, under a controlled atmosphere and temperature.

The activation process significantly increases the surface area per unit volume of a fine network of submicroscopic pores which is what gives activated Carbon its ability to act as a filter material. The specific source of the Carbon and the specific activation process determines the physical characteristics of the finished product. There are many different grades of activated Carbon, and therefore they must be selected specifically for each and every application.

Usage tips

The adsorption activity of the Carbon media relies on a good Carbon/water contact, and therefore moderately active water flow will increase the efficiency.

Strong water flow will reduce the contact time and interfere with the adhesion process of the organic molecules to the Carbon.

Strong water flow may also cause the granules to grind against each other, releasing Carbon material to water.

For best results:

- Remove any fines, by rinsing Carbon under tap water.

- Due to air trapped in the pores Carbon will float, and therefore it is recommended to soak the Carbon in RO water until all of the air has been released.

- Place the Carbon in a location with an active flow of 1000-1500 lph (250-400 gph) per 50 gr carbon.

- Replace Carbon every 1.5 – 2 months. Note: When Carbon becomes saturated with organics, it may start adsorbing some of the trace elements from the seawater.